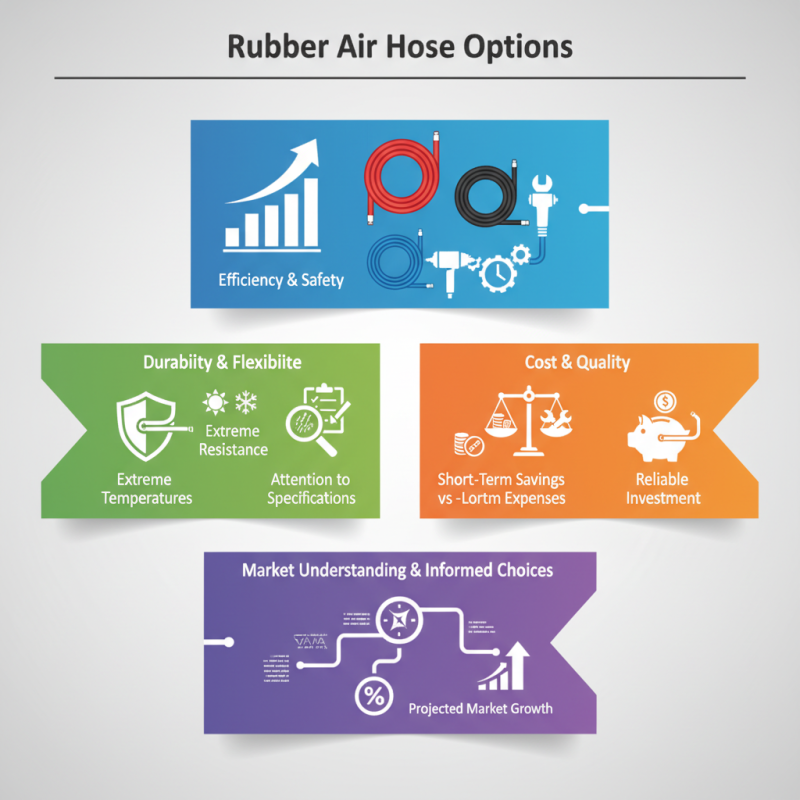

The choice of the best rubber air hose for your projects can greatly impact efficiency and safety. According to industry reports, the rubber air hose market has seen steady growth, projected to expand at a CAGR of 5.2% over the next five years. “The right air hose ensures optimal performance and longevity,” says John Smith, a seasoned expert in pneumatic tools. His insight underlines the importance of selecting high-quality materials.

rubber air hoses stand out due to their durability and flexibility. They are designed to withstand extreme temperatures and resist abrasions. Yet, not all rubber air hoses are created equal. Some may not perform well under heavy-duty conditions, leading to issues in crucial projects. Attention to specifications is key.

Furthermore, cost is a vital consideration. Affordable options can sometimes lead to compromises in quality. While it's tempting to cut costs, doing so can result in long-term expenses. Investing in a reliable rubber air hose is usually wise. Understanding the nuances in the market can guide choices effectively.

When selecting a rubber air hose, consider its flexibility. A flexible hose is vital for ease of movement and storage. You want it to bend without kinking. This ensures a smooth flow of air, which makes your work easier. A stiff hose can be cumbersome and restrictive.

Another important feature is the hose diameter. Typically, a wider diameter allows for a greater airflow rate. It can also handle more air pressure. However, a larger diameter may be heavier. Balancing size and weight can be challenging. You don't want to compromise on performance for portability.

Durability is crucial too. Look for a hose that can withstand wear and tear. Check the materials used. Some may not be as robust as claimed. Assessing user reviews can provide insights. Remember, not every product lives up to its marketing. This process may take some time, but it's worth it in the long run.

| Hose ID (inches) | Length (feet) | Max Pressure (psi) | Temperature Range (°F) | Weight (lbs) | Highlights |

|---|---|---|---|---|---|

| 1/4 | 50 | 300 | -40 to 200 | 5.0 | Flexible, Durable |

| 3/8 | 100 | 250 | -20 to 150 | 8.0 | Oil Resistant, Lightweight |

| 1/2 | 75 | 200 | -10 to 180 | 7.5 | Heavy-duty, Weather Resistant |

| 5/8 | 50 | 350 | -40 to 210 | 9.0 | Super Strong, Abrasion Resistant |

| 3/4 | 25 | 150 | -20 to 170 | 6.0 | Compact, Easy to Handle |

When choosing rubber air hoses, material matters significantly. Not all rubber is created equal. Some rubber hoses are more durable, while others can wear out quickly. For instance, synthetic rubber blends often resist oil and ozone, making them suitable for various environments. In contrast, natural rubber has excellent elasticity but may deteriorate under harsh conditions.

Durability varies widely. Consider how each material reacts to temperature changes. A hose that works well in hot weather might crack in the cold. Flexibility is also crucial. A stiff hose can be challenging to maneuver, leading to frustration and inefficiency.

To get the most out of your hose, exploring different options is essential. Compare thickness, weight, and abrasion resistance. Not all projects require the same specifications. Reflect on previous experiences; perhaps you overlooked the hose material before. Small mistakes can lead to bigger issues later on.

When choosing rubber air hoses for various projects, it's vital to consider quality and brand reliability. Industry reports indicate that high-quality rubber hoses can handle temperatures ranging from -40°F to 190°F, making them versatile for different environments. Many professional users prefer hoses that are resistant to abrasion and kinks. It is essential to evaluate whether the hoses meet your specific project needs.

The market offers several reputable options that excel in durability and performance. Studies reveal that reinforced rubber hoses tend to last longer under constant pressure and high usage. Some hoses can withstand pressures of up to 300 PSI, which is significant for heavy-duty tasks. However, despite these advantages, users often report issues with hose weight and flexibility.

A critical aspect to assess is the number of working hours you expect from the hose. Some users find that lower-priced hoses do not meet long-term performance expectations. Being cautious about initial investment can lead to potential future costs. Understanding these variables and choosing a hose that aligns with project requirements is paramount for success.

This chart illustrates the weight of different rubber air hose sizes per 100 feet. The data indicates that as the diameter of the hose increases, the weight also increases, which is crucial information for project planning and material handling.

Rubber air hoses are versatile tools in both DIY and professional settings. They are commonly used in various tasks like powering pneumatic tools, inflating tires, and painting projects. The flexibility of rubber hoses allows for easy maneuvering around job sites. They can withstand high pressures, making them reliable for heavy-duty applications. However, the weight of rubber hoses can make them cumbersome. Users often find it difficult to transport them.

In DIY projects, rubber air hoses are perfect for casual tasks like inflating sports equipment or camping gear. These hoses are often treated with a protective coating, keeping them durable in different weather conditions. Yet, experiencing kinks or tangles can be frustrating. It teaches users to store hoses more carefully. The connection to air compressors can also lead to leaks if not done properly. Regular inspections are necessary to avoid such issues.

Professionals use rubber air hoses for more demanding applications. They rely on them for construction tools and automotive repairs. The grip and flexibility allow for precision work. Still, one must remember that maintenance is key. Cracks and wear can compromise performance. Neglecting them may result in decreased efficiency and safety hazards. It's a common oversight that can lead to bigger problems down the line.

Rubber air hoses are essential for various projects. To ensure they last, proper maintenance is crucial. Regularly inspect your hose for any signs of wear. Look for cracks or abrasions that could lead to air leaks. If you notice damage, replace the hose immediately. Waiting could result in more severe issues later, like decreased efficiency.

Storage is equally important. Avoid keeping your hose in extreme temperatures. Heat can cause the rubber to degrade quickly. Store it in a cool, dry place, away from direct sunlight. Coiling the hose carefully will prevent kinks and knots that may weaken it. Each time you use it, roll it out straight to avoid future problems.

Cleaning your hose is another helpful tip. Sometimes, dirt and debris can cause blockages. A simple rinse with water can help remove any build-up. Just ensure it dries completely before storing. Leaving it damp can lead to mold or other issues. Reflect on your maintenance habits. Are you diligent about checking and cleaning? Small changes can significantly enhance the longevity of your rubber air hose.

Let us help you get started with our superior LED lighting products.

Get all the latest news from BrightLED.

Copyright © Bright LED. All rights reserved.

STAY CONNECTED